|

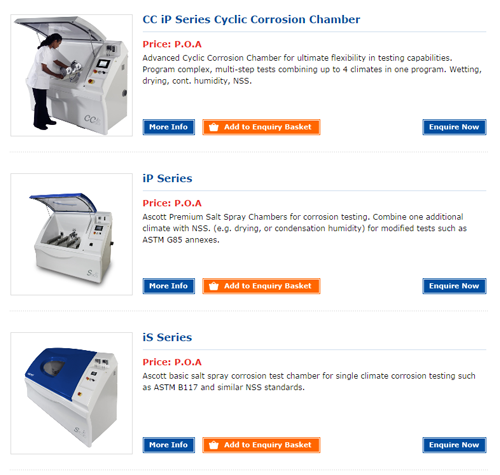

Corrosion Chambers - AustraliaWe sell Salt Spray Chambers or Corrosion Testing chambers in Australia. Call us to discuss your application including basic ASTM-117B and ISO 14993through to complex, multiple climate automotive tests such Ford CETP L-467 and for many more. Environmental Testing Chamber's that are specifically design to measure the rate of corrosion are called Salt Spray Chambers, Salt Spray Cabinets or Cyclic Corrosion Chambers. The purpose of these units is to measure the rate of corrosion resistance in a controlled corrosive environment. The chamber or cabinet itself, is a closed testing chamber that conducts a Salt Spray test. The most common tests are based on the standard's ASTM-B117 and ISO 9227. Typically a salt solution of 5% (Sodium Chloride) is atomized via nozzles into the testing equipment chamber. This creates a highly corrosive environment of salt fog so that the exposed testing samples are subjected to sever corrosive conditions. The test equipment provides a controlled environment which includes Temperature and humidity depending on the models. The samples or parts for testing are evaluated at set periods of time to evaluate the appearance of oxides. Oxides are visible as a product of corrosion and these are evaluated to determine the resistance of the material, lining or protective finish applied to the sample for testing. A Salt Spray Chamber is an effective way to determine the resistance of surface finishes that would only otherwise be determined from years of natural weathering. Salt Spray testing is popular way of testing for corrosion because it is well standardized, repeatable (within reason), quick and inexpensive. Testequip Pty Ltd is the Australian & New Zealand agent for Ascott. Ascott Chambers are manufactured in Britain and are of the highest quality. We have a range of information and specifications on our website www.te2.com.au that details the options and Models that are available. These options of Chambers are dependent on the standards being tested to, and the result you are trying to achieve. Below is more information on the types of tests that can be done. Ascott continue to develop and improve their chambers and we are proud to announce the new range of Atmosfär of 1300 lt and 2600 lt cyclic chambers with oscillating, magnetically coupled, overhead spray bar, separate air conditioning unit and high velocity vertical air-flow. These Atmosfär have been specifically designed for automotive testing. |

|

Click here for more details |

There are various types of Salt Spray tests, the most common ones include;

NSS – Neutral Salt Spray

ASS – Acetic Acid Test

CASS – Copper Chloride

Each are tested for various reasons but the most common type is NSS – Neutral Salt Spray.

There are two types of Chambers;

Salt Spray Corrosion Test Chambers – Salt Spray test (also known as the Salt Mist or Salt Fog test) has been the standard or benchmark testing cabinet for most industries. There are many standards written around this internationally and it is a popular choice due a comparative test in a relatively short period of time. It allows testing to be conducted in accordance with a standard to compare if the product meet or exceeds satisfaction in accordance to expectation.

Cyclic Corrosion Test Chambers (CCT) - The Cyclic Corrosion test is a means of accelerating the nature of the corrosive environment. The test Chamber allows for differential and multiple temperature & humidity profiles to run simultaneously or con-currently. This is a very useful way of recreating and testing for specific environmental conditions. For example, it controls environmental conditions such as rainfall followed by extreme temperature and humidity, followed by further rainfall.

Ascott Analytical

As mentioned the Ascott chamber is of the highest quality and Ascott Analytical are at the forefront of chamber design. For many years Ascott’s research and development have led the market with Salt Spray chamber quality and design. It is this technical excellence that allow Ascott to supply chambers into all parts of the world. Testequip, TE2 or te2.com.au are proud to have been a partnering agent for the past 10 years and have supplied over 50 salt spray chambers to the Australian and New Zealand Industrial Markets.

We have supplied Chambers into the following Areas;

- Department Of Defense

- Research & Development

- Universities

- Healthcare

- Pharmaceutical

- Automotive

- Domestic Fittings & Fixtures

- Coatings & Texture

- Metal

- Mining

- Aeronautical

- Contract Testing laboratories that provide NATA Certification

- Naval

- General Manufacturing

Plus many more General Industrial Applications.

In fact Salt Spray Testing can apply to almost any product that is exposed to our harsh Australian & NZ environment’s. Ascott has a range of Chambers and accessories and factory fitted or retro fitted to the salt cabinet. The chambers come is 4 sizes ranging from 120 litres up to 2000 litres. They also can be supplied in either standard or premium configurations.

Ascott offer specific accessories that are required for compliance to standards, such as Top Down wetting (Rain Simulation), dehumidification and refrigeration for example. Ascott Salt spray chambers also provide many options that are purely for user friendly application such as;

- Internal Lighting

- Exit condensation scrubbing

- Easy access loading

- Clear front for visual inspection

- Access ports for Calibration and data logging

- Data logging and Ethernet connection for remote monitoring.

Plus many more.

Please Contact us so that we can offer you the correct Salt Spray Chamber or Cyclic Corrosion Chamber that would best suit your requirements and Standards tested. Our friendly team at Testequip & TE2 are technically backed by the team at Ascott and we can assist you with ay technical enquiry.

We look forward to hearing from you with your Corrosion testing requirements.

© 2014 corrosionchamber.com.au. | All Rights Reserved.